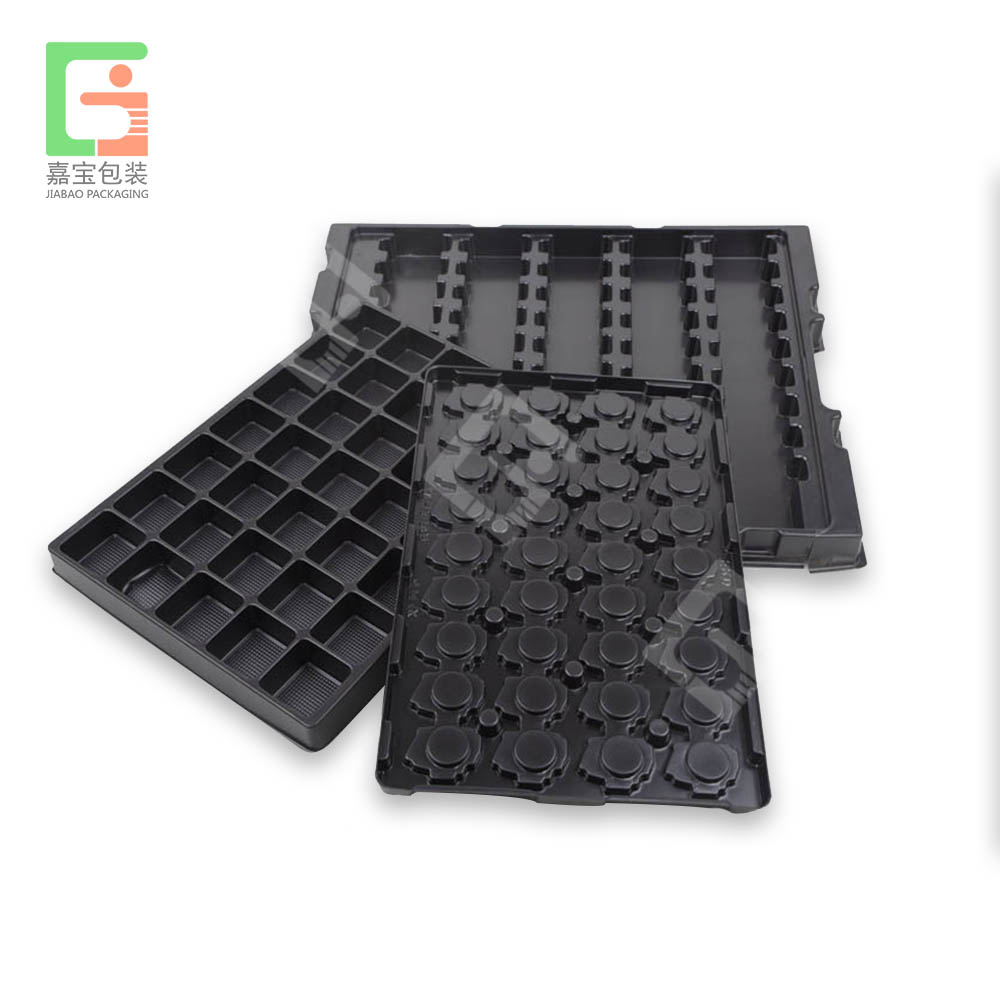

Antistatic masterbatch for anti-static vacuum tray

What are the application scope of anti-static masterbatch for anti-static vacuum tray? Antistatic masterbatch is obtained by high-speed mixing, extrusion molding, and cutting of carriers and anti-static systems, which is used to reduce the surface resistance of materials and prevent the adverse effects of static electricity on various industrial sectors and humans. Also known as anti-static masterbatch, high polymers are insulators under normal circumstances, with a surface resistance of 10 ^ 12 Ω or above. Anti static packaging materials require a surface resistance of 10 ^ 7-10 ^ 11 Ω. The application scope of anti-static masterbatch includes: anti-static trays, electronic component vacuum forming turntables, PCBA anti-static trays, electronic component trays, IC chip vacuum forming trays, anti-static vacuum forming trays, and so on.

Anti static tray

The anti-static masterbatch of anti-static vacuum tray can be suitable for molding and processing methods such as vacuum tray, injection molding, extrusion molding, etc; It can be evenly dispersed inside the plastic product, and reduce its surface resistivity and disperse surface charge density by migrating active factors and nanomaterials from the masterbatch to the surface of the plastic product, thereby achieving anti-static effect; And improve the following undesirable phenomena in plastic products:

From the perspective of aesthetics and hygiene, for most anti-static vacuum trays, it is necessary to prevent dust adsorption during storage and use to avoid affecting the appearance and performance of the product.

When processing blister trays with a large area, such as films and fibers, the force generated by static charges greatly interferes with the processing process, hindering the normal winding of films and fibers, and the printability of products is also affected by static charges.

3. High static charges causing discharge can damage the performance of products, such as the packaging and disassembly of electronic chips, as well as the normal operation of high-precision instruments such as electronic communication and medical devices.

Spark discharge can cause serious accidents: for example, in flammable and explosive places, charge discharge can lead to fire or explosion.

Anti static vacuum tray

The anti-static masterbatch of anti-static trays is now widely used in injection molding, blow molding, vacuum molding trays, coating, drawing, engineering plastics, transparent sheets, polypropylene, polyethylene, PP, PE, PS, PET, ABS, POE, HDPE, LDPE, TPE, TPP, PC, PA, PVC, EBS, HIPS, BOPP, TCEP, EVA and many other products.